Automation in the packaging industry has made significant strides, driving both efficiency and precision. Among the key innovations are case packers and the Pick and Place Robot. These machines are transforming how products are handled, packed, and shipped in industries like food, beverage, pharmaceuticals, and consumer goods. This article explores how case packers and Pick and Place Robots enhance productivity and streamline operations in modern packaging systems.

The Role of Case Packers in Packaging

Case packers are automated systems designed to load products into cartons or cases. These machines have become essential in high-speed packaging lines, where they quickly and efficiently pack items such as bottles, cans, or bags into their final shipping boxes. The integration of case packers reduces the need for manual labor, speeds up the production process, and enhances the accuracy of packaging. These systems help ensure that products are securely packed, preventing damage during transportation and ensuring customer satisfaction.

Pick and Place Robots: Revolutionizing Handling Systems

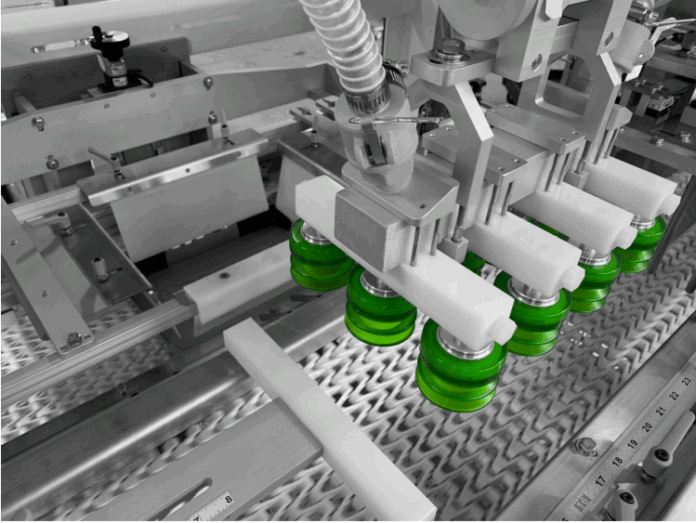

The Pick and Place Robot is an innovation that plays a crucial role in packaging and handling processes. These robots are designed to pick items from one location and place them into another, often with high precision and speed. In the packaging industry, Pick and Place Robots are used to load products onto conveyors, pack items into boxes, or organize products for distribution. The robots’ ability to handle a variety of products, from fragile items to irregular shapes, makes them indispensable in modern packaging lines.

How Case Packers Enhance Efficiency

One of the primary advantages of case packers is their ability to handle large volumes of products at a consistent speed. These machines eliminate the need for manual labor in the packing process, reducing human error and increasing the speed at which products are packed into shipping cartons. By automating the packing process, case packers allow manufacturers to increase their throughput and meet growing consumer demands without compromising on the quality or safety of the packaging.

Pick and Place Robots for Versatile Operations

Pick and Place Robots offer incredible versatility in packaging lines. These robots are highly adaptable and can be programmed to handle different tasks, such as sorting, packing, and palletizing. Whether it is moving fragile glass bottles, irregularly shaped boxes, or delicate food items, Pick and Place Robots can adjust their operations to handle a wide range of products. The flexibility and precision offered by these robots significantly enhance the overall efficiency of packaging systems, making them an invaluable asset for businesses aiming to scale operations.

Reducing Labor Costs with Automation

The integration of case packers and Pick and Place Robots helps companies reduce labor costs significantly. These machines can operate continuously, reducing the need for manual labor in repetitive tasks. In industries where labor shortages can affect production timelines, automation through case packers and Pick and Place Robots ensures that operations run smoothly without interruptions. By automating these processes, companies can allocate resources more efficiently, allowing workers to focus on higher-value tasks and improving the overall productivity of the packaging line.

The Future of Case Packers and Robots

As the demand for faster, more efficient packaging solutions grows, the future of case packers and Pick and Place Robots looks promising. Innovations such as artificial intelligence, machine learning, and advanced robotics are enabling machines to become smarter and more adaptable. Future developments will likely lead to even faster and more precise systems, with robots that can perform multiple tasks simultaneously and case packers that can handle more complex packaging requirements. Automation in packaging will continue to evolve, further driving efficiencies and reducing costs in the industry.

Conclusion

The integration of case packers and Pick and Place Robots has significantly improved the packaging industry by enhancing speed, precision, and efficiency. These automated systems play a vital role in modern production lines, reducing labor costs and ensuring higher productivity. As technology continues to evolve, both case packers and Pick and Place Robots will become even more advanced, making packaging operations more intelligent and efficient. For more insights into packaging automation, visit the domain where cutting-edge solutions are transforming the industry.